What are RF MEMS and RF SOI technologies? Who is the overlord of future radio frequency technology?

What is RF MEMS?

The so-called RF MEMS is an RF product processed with MEMS technology. RF-MEMS technology is expected to achieve a high degree of integration with MMIC, making it possible to make a system integration chip (SOC) that integrates information acquisition, processing, transmission, processing and execution. According to the concept of microelectronics technology, not only can wafer-level production and mass production, but also have the advantages of low price, small size, light weight and high reliability. RF MEMS devices can be divided into two main categories: one is called passive MEMS, and its structure has no moving parts; the other is called active MEMS, which has a movable structure. Under the action of electrical stress, the movable parts will Deformed or moved. Its key processing technologies are divided into four categories: planar processing technology, bulk silicon corrosion technology, solid-phase bonding technology, and LIGA technology.

Radio frequency microelectromechanical system (RF MEMS) is one of the important application areas of MEMS technology, and it has also been a research hotspot in the MEMS field since the 1990s. RFMEMS is used for signal processing in radio frequency and microwave frequency circuits, and is a technology that will have a significant impact on the radio frequency structure of existing radars and communications. With the advent of the information age, in the field of wireless communications, especially in the fields of mobile communications and satellite communications, there is an urgent need for new devices with low power consumption, ultra-miniaturization and planar structures that can be integrated with signal processing circuits. Cover wide frequency bands including microwave, millimeter wave and submillimeter wave. However, there are still a large number of indispensable off-chip discrete components in current communication systems, such as inductors, variable capacitors, filters, couplers, phase shifters, switch arrays, etc., which have become the bottleneck restricting the further reduction of system size. The emergence of RF MEMS technology is expected to solve this problem. Passive devices manufactured using RF MEMS technology can be directly integrated with active circuits in the same chip to achieve high on-chip integration of radio frequency systems, eliminate parasitic losses caused by discrete components, and truly achieve high cohesion and low Coupling can significantly improve the performance of the system.

What are the advantages of RF SOI over RF MEMS?

First of all, the RF SOI process can work at a very high frequency, Ft/Fmax meets the requirements of 3 to 5 times the millimeter wave operating frequency; RF SOI can achieve device stacking, thereby improving the power and energy efficiency ratio at the same time; third, RF SOI The substrate used in the process reduces parasitic effects, so that the manufactured RF chip has a higher quality factor, lower loss, and better noise figure. At the same time, this substrate also improves the insulation level and linearity of the product; fourth, RF SOI can integrate logic and control functions, which cannot be achieved by GaAs technology. Therefore, GaAs devices need to be equipped with a control chip in the application. Using RF SOI technology, PA and control functions can be integrated on a chip. While reducing costs, it also saves valuable PCB area. Finally, RF-SOI has a back-gate bias function, which can be used to fine-tune the millimeter-wave radio frequency circuit to meet the needs of use.

After reviewing the development history of China's smartphone industry, Wang Qingyu, general manager of Simao Technology, pointed out that with the increase in the number of smartphones, the demand for RF-SOI has also increased rapidly, which has brought a rare opportunity for China to develop RF-SOI. Opportunities, but there are also many challenges.

Which of these two technologies is more suitable for the future?

The RF device and manufacturing process market is heating up, and this trend is particularly evident for the two key components used in smartphones-RF switching devices and antenna tuners. RF device manufacturers and their foundry partners continue to introduce traditional RF switch chips and tuners based on RF SOI process technology for today’s 4G wireless networks. Recently, GlobalFoundries introduced a 45nm RF SOI process for future 5G networks. RF SOI is the RF version of silicon-on-insulator (SOI) technology, which takes advantage of the high resistivity characteristics of the built-in isolation substrate.

In order to change the market structure, Cavendish KineTIcs, a fabless IC design company, is launching a new generation of RF products and antenna tuners based on the alternative process RF MEMS.

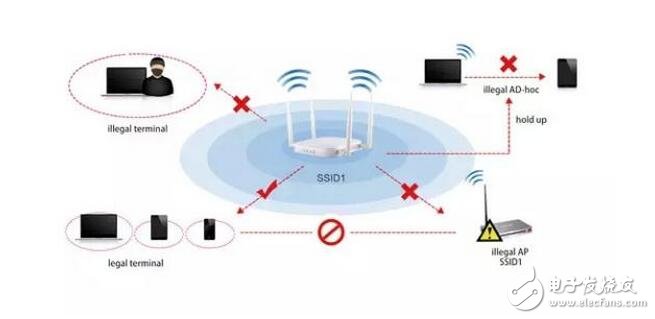

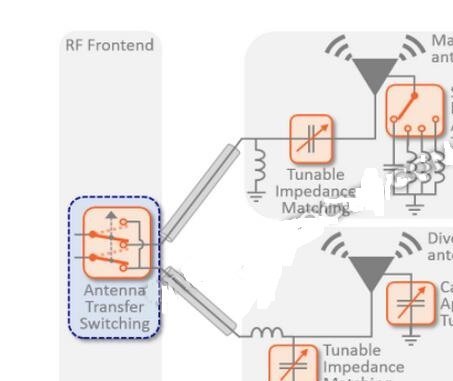

RF switch and tuner are two key components in the RF front-end module of mobile phone. The RF front-end integrates the send/receive function of the system. Among them, the RF switch routes the wireless signal, and the tuner helps to adjust the antenna to any frequency band.

Even without considering the changes in RF equipment and process types, the challenges of today's RF market are daunting enough. Paul Dal Santo, President and CEO of Cavendish KineTIcs, said: “A few years ago, RF was a fairly simple design, but now things have changed drastically. First, your RF front-end must handle a very wide range The frequency band extends from 600MHz to 3GHz. With the advent of more advanced 5G technology, the frequency band will be further extended to 5GHz to 60GHz. This brings some incredible challenges to front-end RF designers."

Mobile phone OEMs must face this challenge, make trade-offs, and consider choosing new components. Specifically, for RF switches and antenna tuners, it can be attributed to two technologies-devices based on RF SOI process and RF MEMS process.

RF SOI is a manufacturing process currently in service. Devices based on RF SOI technology can meet current requirements, but they are beginning to encounter some technical problems. In addition, there are still price pressures in the market. As devices migrate from 200mm to 300mm wafers, it will also cause some problems.

In contrast, RF MEMS has some interesting characteristics and has made progress in some areas. In fact, Cavendish KineTIcs said its MEMS antenna tuner based on RF MEMS process is being used by Samsung and other OEMs.

Chris Taylor, an analyst at Strategy AnalyTIcs, said: "RF MEMS can provide very low on-resistance, thereby reducing insertion loss. However, RF MEMS lacks a production track record, and high-volume wireless system OEMs will not blindly focus on new technologies and small Suppliers pay. Of course, compared with RF SOI devices, the price of RF MEMS must be sufficiently competitive, but there is another major obstacle that OEMs need to verify product reliability and need reliable sources of supply."

RF front end

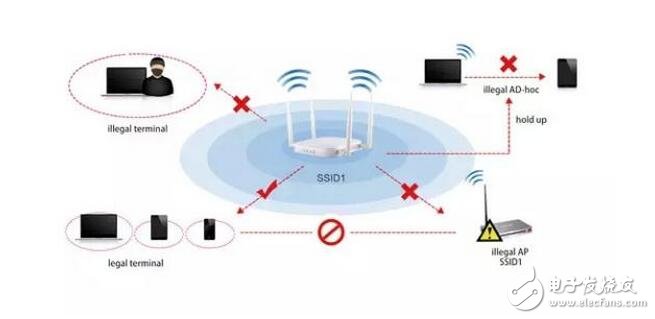

Smart phones are a big market that mixes RF switches, antenna tuners, and other components in the business environment. Its data is worth looking at. According to data from Pacific Crest Securities, in 2017, global smartphone shipments are expected to grow by 1%. In 2016, the annual growth rate of smartphones was only 1.3%.

On the other hand, according to Yole Développement's data, the market size of RF front-end modules/components for smartphones is expected to jump from USD 10.1 billion in 2016 to USD 22.7 billion in 2022. According to Strategy Analytics, in 2016, the RF switchgear market was worth US$1.7 billion.

As OEMs continue to add more RF components to smartphones, the RF market is growing. "Multi-band LTE is also becoming popular for low-end devices," said Taylor of Strategy Analytics. "The RF switch component market is growing."

In the process of the mobile phone network shifting to 4G or Long Term Evolution (LTE), the number of RF switching devices for each mobile phone has increased. "The unit of shipments we are talking about is very large," Taylor said. "Nowadays, most RF switch devices (not all) are used in mobile phones, and most of them use RF SOI manufacturing processes. RF MEMS is still an emerging thing and is insignificant compared to RF SOI switches."

Despite the huge shipments of RF switches, market competition is fierce and price pressure is greater. Taylor said the average selling price (ASP) for these devices is 10 to 20 cents.

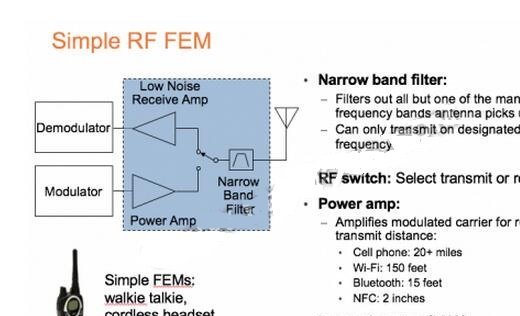

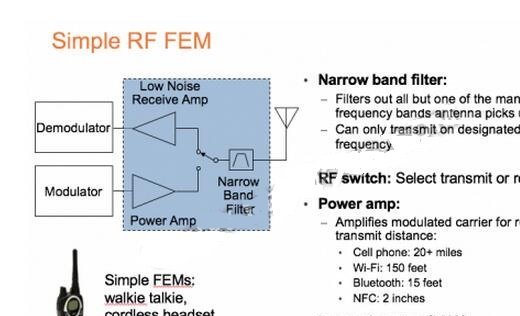

At the same time, in a simple system, the RF front end consists of multiple components-power amplifier, low noise amplifier (LNA), filter and RF switch.

Randy Wolf, a technician at GlobalFoundries, said in a recent speech: "The main purpose of a power amplifier is to ensure that there is enough energy to get your signal or information to its destination.

The LNA amplifies the small signal from the antenna. The RF switch routes the signal from one component to another. "The filter prevents any unwanted signals from entering the back end," Wolf said.

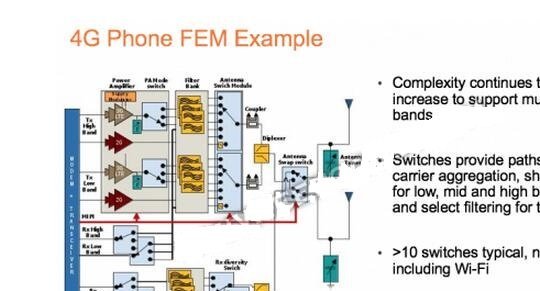

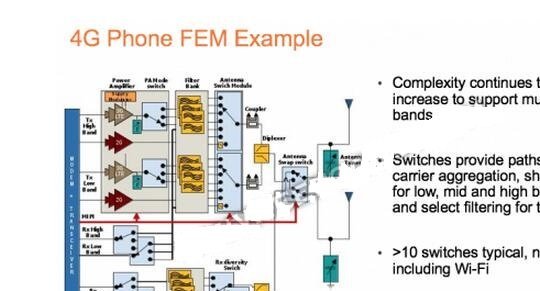

On mobile phones, the radio frequency functions of 2G and 3G wireless networks are very simple. 2G has only four frequency bands, and 3G has five frequency bands. But 4G has more than 40 frequency bands. 4G not only combines 2G and 3G frequency bands, but also carries a series of 4G frequency bands.

In addition, mobile operators have deployed a technology called carrier aggregation. Carrier aggregation combines multiple channels or component carriers into a big data pipeline to achieve higher bandwidth and faster data rates in wireless networks.

In order to cope with multiple frequency bands and carrier aggregation, OEM manufacturers need complex RF front-end modules. Today's RF front-end modules will integrate two or more multimode and multiband power amplifiers, as well as multiple switches and filters. "It depends on the RF architecture used. The number of power amplifiers is determined by the addressable regional frequency bands of the mobile phone." Qorvo Mobile Strategic Marketing Manager Abhiroop Dutta said: "Using a single SKU to deal with multi-regional/global cellular market A typical "full Netcom" mobile phone has a very wide frequency band coverage. In the implementation of the typical integrated RF front-end module of this mobile phone, an engineering choice is to use an RF front-end with a sub-band module to meet the different requirements of high, medium and low frequency bands ."

In contrast, there is another situation where smart phone OEMs may design dedicated phones for specific markets. "An example is a mobile phone for the Chinese mainland market. In this case, the RF front-end needs to support a frequency band unique to the region," Dutta said.

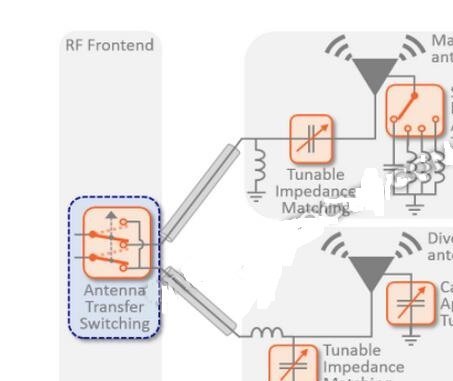

According to Cavendish Kinetics, there are two antennas on LTE mobile phones, the main antenna and the diversity antenna. Basically, the main antenna is used for transmitting/receiving functions, and the diversity antenna is used to increase the downlink data rate of the mobile phone.

In actual operation, the signal first reaches the main antenna and then moves to the antenna tuner, which allows the system to adjust to any frequency band. Then, the signal enters a series of RF switches. "It converts to the applicable frequency band you want to use, such as GSM, 3G or 4G," said Wolf of GlobalFoundries. "From there, the signal enters the filter, then the power amplifier, and finally the receiver."

Considering this complexity, mobile phone OEMs face some challenges, and power consumption and size are critical. "Due to this complexity, the signal will suffer more loss at the front end, which will have a negative impact on the overall noise figure of your receiver," Wolf said.

Obviously, the RF switch plays a key role in solving this problem. In general, a smart phone may contain more than 10 RF switch devices. The basic RF switch uses a single pole single throw (SPST) configuration. This is a simple on-off switch.

Today, OEM manufacturers use more complex switch types. Ron * Coff is the key indicator of RF switches. According to Peregrine Semiconductor, "Ron * Coff reflects how much loss (Ron or on-resistance) the RF signal occurs when the switch is in the "on" state, and how much energy the RF signal leaks through the capacitor when the switch is in the "off" state ( Coff or turn-off capacitance) ratio."

All in all, what OEM manufacturers need is an RF switch with no insertion loss and good isolation. Insertion loss relates to the loss of signal power. If the RF switch does not achieve good isolation, the system may encounter interference. “In general, the challenge for RF front-ends is to support the ever-increasing performance requirements and keep up with evolving standards and increasing frequency band coverage. Not only that, as mobile phones become thinner, the package size of RF solutions is also In shrinking. Qorvo's Dutta said that key indicators such as insertion loss, antenna power and isolation are still driving forces for the continuous development of RF product portfolio solutions.

solution

Today, the power amplifier of mobile phones mainly uses gallium arsenide (GaAs) technology. A few years ago, OEMs migrated manufacturing processes such as radio frequency switches from GaAs and sapphire (SoS) to RF SOI. GaAs and SoS are variants of SOI, and as RF switches become more and more complex, these two processes become too expensive.

RF SOI is different from completely exhausted SOI (FD-SOI) and is suitable for digital applications. Similar to FD-SOI, RF SOI has a very thin insulating layer in the substrate, which can achieve high breakdown voltage and low leakage current.

Peter Rabbeni, Head of GlobalFoundries RF Business Unit, said: "The mobile market continues to be optimistic about RF SOI because it can provide low insertion loss, low harmonics and high linearity over a wide frequency range, achieving good performance and cost-effectiveness."

Today, companies such as Qorvo, Peregrine, and Skyworks provide RF switches based on RF SOI. Usually, RF switch manufacturers use foundries to manufacture these products. GlobalFoundries, STMicroelectronics, TowerJazz and UMC are leaders in the RF SOI foundry business.

Therefore, OEMs have multiple choices in component suppliers and foundry products. Usually, foundries provide RF SOI processes, covering nodes from 180nm to 45nm and different wafer sizes.

Deciding which node to use depends on the specific application. Wu Kun, vice president of business management of UMC, said: "With regard to the specification of RF SOI technology, everything is to consider technical solutions suitable for terminal applications from the perspective of technical performance, cost and power consumption."

Even with multiple options, RF switch manufacturers face some challenges. The RF switch itself contains a field effect transistor (FET). Like most devices, FETs are affected by unwanted channel resistance and capacitance.

In RF switches, FETs are used in stacks. Generally speaking, 10 to 14 FETs are stacked in today's RF switches. According to experts, as the number of FETs increases, devices may encounter problems related to insertion loss and resistance.

Another problem is capacitance. Skyworks published in 2014 an article entitled "The latest developments and future trends of SOI technology in RF applications", said, "In RF switches, 30% or more of the unwanted capacitance comes from the interconnection in the device. The interconnection is a metal layer or micro-wiring scheme, including RF SOI-based switches.

Generally, in 4G mobile phones, the mainstream manufacturing process for RF switches is 180nm and 130nm nodes on 200mm wafers. Many (but not all) interconnect layers are based on aluminum. Aluminum interconnects have been used in the IC industry for many years and are inexpensive, but they also have higher capacitance.

Therefore, copper is used in selected layers in RF devices. Copper is a better conductor and has less resistance than aluminum. Ng said: "The traditional metal stack used in 130nm RF CMOS process products includes cost-effective aluminum interconnect layers and performance-advantaged copper interconnect layers." This is the best solution to balance cost and performance. RF SOI solutions usually contain a certain number of aluminum metal layers and one or more copper layers.

Usually, copper is used as an ultra-thick metal layer on the top layer to help improve passive device performance. He said: "It is best to use a thick top metal like copper, which can minimize ohmic losses and improve performance."

Recently, RF equipment manufacturers have migrated from 200mm wafers to 300mm wafers, and their process nodes have also migrated from 130nm to 45nm. Generally, 300mm fabs only use copper interconnects.

Using only copper interconnects, RF switch manufacturers can reduce capacitance. However, 300mm wafers have increased manufacturing costs, causing some contradictions in the market. On the one hand, cost-sensitive mobile phone OEMs require RF switches to keep their prices low. On the other hand, RF switchgear manufacturers and foundries hope to maintain profits.

"Today, very few RF SOI devices are produced on 300mm wafers," Ng said. "There are many reasons for this situation, including the cost/availability of the 300mm RF SOI substrate, and the infrastructure to support post-silicon processing. However, we expect that these challenges will be significant in the next few years. The above is resolved, and then most of the high-volume RF SOI applications will migrate to 300mm wafers."

Prior to this, the industry may face a supply and demand problem of 300mm. "We believe that before more production migrates to 300mm wafers, the market will always face the challenge of short supply. How fast the production capacity is launched and how large the demand is will be reflected in the contradiction between supply and demand." He said.

Today's RF SOI process is suitable for 4G mobile phones. GlobalFoundries hopes to stand out in the 5G competition, and recently launched a 45nm RF SOI process for 5G applications. This process utilizes an SOI substrate enriched with high resistance wells.

5G is an upgrade of 4G networks. Today's LTE network frequency band is between 700 MHz and 3.5 GHz. In contrast, 5G will not only coexist with LTE, but will also operate in the millimeter wave band between 30 GHz and 300 GHz. 5G will increase the data transmission rate to more than 10Gbps, which is 100 times that of LTE. But the large-scale deployment of 5G is expected in 2020 and beyond.

In any case, 5G needs a new component. "(45nm RF SOI) is mainly focused on the 5G millimeter wave front end. It integrates PA, LNA, switch, and phase shifter to create an integrated millimeter wave controllable beamformer for 5G systems.” said Rabbeni of GlobalFoundries.

There are other solutions for 5G, and RF MEMS is one of them. In addition, TowerJazz and the University of California, San Diego recently demonstrated a 12Gbps 5G phased array chipset. The chipset uses TowerJazz's SiGe BiCMOS technology.

Which process will win? Only time will tell us the answer. "It is not clear whether RF MEMS has an advantage in 5G applications," said Taylor of Strategy Analytics.

What is RF MEMS?

RF switches based on RF SOI will continue to dominate, but the new technology RF MEMS may also have a certain living space. "Over time, SOI has made incredible progress. Resistance has dropped and linearity has become better." said Dal Santo of Cavendish Kinetics. "But the essence of an SOI switch is that a transistor is turned on or off. When it is turned on, the performance is not very good, and when it is off, it is not very good.

For many years, RF MEMS technology has been advancing steadily. Today, Cavendish, Menlo Micro and WiSpry (AAC Technologies) are developing RF MEMS for mobile applications.

RF MEMS is different from sensor-based MEMS such as gyroscopes and accelerometers. The sensor MEMS converts mechanical energy into electrical signals. In contrast, RF MEMS only conducts signal transmission.

Initially, companies such as Cavendish applied RF MEMS technology to the antenna tuner market using RF SOI and other processes.

"If the antenna is fixed, we cannot make it support the different frequency bands needed. So the antenna needs to be adjusted," Dal Santo said. "Now, the main method is to switch, either switch between different fixed capacitors, or switch between different fixed inductors. The problem is that the antenna is a high-Q device. You have to be careful, otherwise it will cause a loss of radiation performance."

In contrast, Cavendish's tuner has 32 different capacitance ranges. "They are fully programmable and have very good high-Q performance. So the radiation performance loss is very low. You can use these to adjust the antenna to the frequency range you need to support." He said.

Looking to the future, Cavendish plans to adopt RF SOI devices in the larger RF switch field. He said: "If you replace RF SOI with a real switch, it is a MEMS switch, and the insertion loss of your receiver or transmitter will be reduced." He said.

However, will RF MEMS devices replace RF SOI-based devices? On this issue, TowerJazz can provide some insights. TowerJazz provides traditional RF SOI technology and is also a foundry supplier of Cavendish's RF MEMS devices.

"RF MEMS and RF SOI may have some small overlaps in competing for the same applications. Generally speaking, they are complementary. RF MEMS is used for the most demanding applications, and RF SOI is used for the remaining applications," TowerJazz Said Marco Racanelli, senior vice president and general manager of the RF/High Performance Analog Business Unit.

"RF SOI technology will continue to evolve and it is still available for RF switching applications and some low-noise amplifier markets," Racanelli said. "However, in some special applications, alternative technologies such as SiGe for low-noise amplifiers and MEMS for switches can provide better linearity or lower loss. In short, RF SOI will continue to be an expanding market. Services, other technologies will also develop."

RF MEMS has taken a place in the antenna tuner market, and whether it can extend its antennae to the RF switch business remains to be verified. "In the future, compared to the built-in RF SOI, RF MEMS can help increase the data rate of mobile phones by providing more linear and lower loss switches." He said. "In RF MEMS, metal plates can be directly contacted in the "on" state to form a metal, low-loss, linear connection. Higher linearity allows more frequency bands and more complex modulation schemes, thereby increasing the phone’s Data rate.

Our other product: